SKF Seals

Sealing in Performance, Powering Reliability.

Enhancing System Performance With SKF Power Transmission Seals

Precision Sealing Solutions For Demanding Applications

SKF power transmission seals are designed to provide exceptional protection against contaminants, retain lubrication, and operate reliably under high-speed and heavy-load conditions. Whether used in rotating shafts, off-highway equipment, or industrial machinery, these seals help reduce friction, prevent wear, and support extended equipment life. E Rail Trans supplies a comprehensive range of SKF sealing solutions engineered for performance across industries.

Request a Quote Today to discover the ideal SKF power transmission seal for your equipment.

Quick Quote Form for Seals

Power Transmission Seals

E Rail Trans supplies a robust selection of SKF radial shaft seals, engineered to maintain critical sealing between rotating and stationary components. These seals consist of two core elements: a cylindrical outer surface for static sealing against the housing bore, and a precision sealing lip that dynamically and statically seals against the shaft. Their design ensures a defined radial load for effective sealing performance under diverse conditions.

Key Features

Chemical- and heat-resistant sealing lip materials

Advanced pump rate performance

Specialised coating offsets housing bore imperfections

Durable construction for heavy-duty usage

Fully compliant with international and national standards

Applications

Gearboxes

Hydraulic pumps

Axles

Power steering columns

Speed reducers

Transmissions

General and heavy industrial shaft systems

SKF Radial Shaft Seal Variants

HMS5 / HMSA10 – Metric rubber OD seals for general industrial use (ISO 6194-1, DIN 3760)

CRW1 / CRWA1 / CRWH1 / CRWHA1 – Inch metal OD seals with SKF WAVE lip for open-end housing bores

CRW5 / CRWA5 – Metal OD, pressure-rated to 50 psi with WAVE lip

HDW1 – Heavy industrial, metal cased with WAVE lip (inch)

CRS1 / CRSH1 / CRSA1 / CRSHA1 – Metal cased with straight lip for general industrial use

PTFE Seals – PTFE lip seals for industrial environments

HM / TL Seals – Grease-lubricated, self-retaining metal OD seals

X Seals – Bore-facing seal lips for effective exclusion

Machined Seals – Custom CNC-engineered sealing solutions

HDS Seals – Heavy-duty metal OD for open-end housings

HDSA / HDSF / HDSH – Metal OD with auxiliary lip, heavy industrial grade

HS / HSS Seals – All-rubber, axially compressed for housings with cover plate

HS / HSS Split Seals – Split rubber variants for easier installation

HDL Seals – High-speed compatible, metal cased for heavy-duty use

TR/3 (HFS) – Fabric-reinforced rubber with spring for axial compression

HRS Seals – Polyurethane axial seals for harsh, heavy applications

Cassette Seals

E Rail Trans offers a robust range of SKF Mudblock cassette seals, designed for optimal retention of grease or oil and superior exclusion of liquid and solid contaminants. These heavy-duty seals are built to order, tailored to match the specific operating conditions of your machinery.

Featured Cassette Seal Variants

MUD11 – Next-generation SKF Mudblock design for oil and grease lubricated applications exposed to extreme environments and operating stress.

MUD6 – Cassette seal optimised for grease-lubricated heavy-duty machinery in challenging conditions.

Explore SKF cassette seals for maximum durability in off-highway and agricultural machinery.

Wear Seals

SKF wear sleeves restore damaged shaft surfaces without disassembly, offering a quick and cost-effective way to extend seal performance. SKF Speedi-Sleeve and LDSLV4 sleeves provide reliable sealing surfaces in standard and heavy-duty applications, reducing downtime and maintenance costs.

Wear Sleeve Options

SKF Speedi-Sleeve

Ultra-thin [0.28 mm] and easy to install, ideal for restoring worn counterfaces up to 203 mm in diameter.LDSLV4 Heavy-Duty Wear Sleeves

Designed for harsh industrial conditions involving solid contaminants.IR .. EGS Inner Rings

Non-directionally ground inner rings for simple counterface setup without machining.

Extend seal service life and reduce costly equipment downtime with SKF wear sleeve solutions.

Maximize Protection With SKF Seals

Reliable Sealing Solutions for Demanding Applications

As an authorized reseller of SKF seals, E Rail Trans delivers high-performance sealing solutions that safeguard equipment, improve efficiency, and extend component life. With poor sealing responsible for costly contamination and system failures, choosing the right seal is essential for reliable operation.

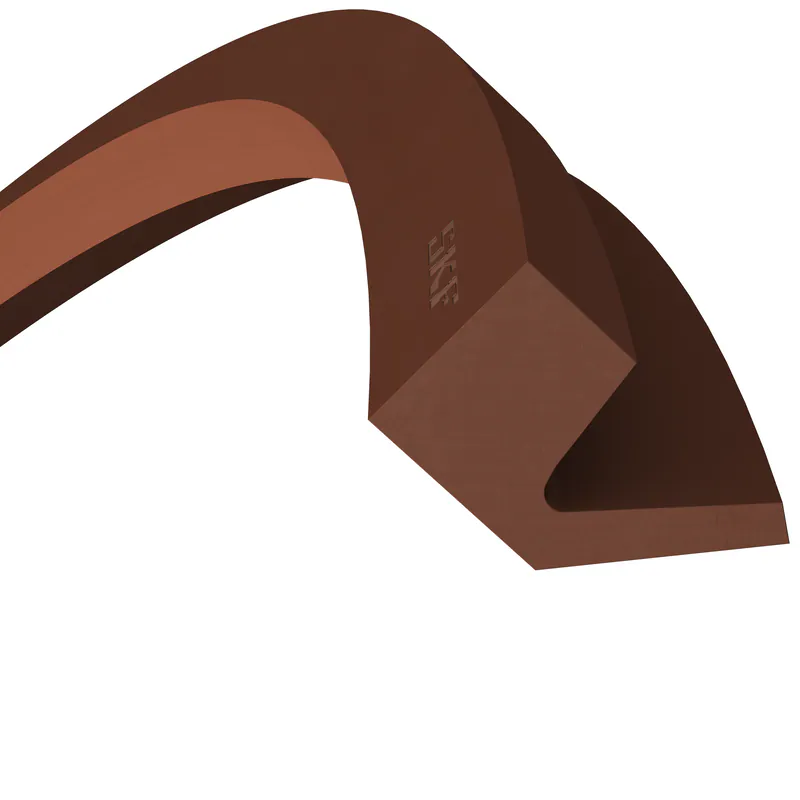

Track Pin Seals

SKF Trackstar seals are engineered for oil-lubricated track chains in off-highway equipment, delivering durable sealing performance in demanding environments. Positioned on the pin connecting a pair of chain links, these seals retain oil, exclude contaminants, and minimise bushing and pin wear.

Key Features & Benefits:

Polyurethane sealing ring with nitrile rubber energiser for optimal sealing performance

Ribbed inner diameter for improved oil distribution and lubrication

Heavy-duty version with metal reinforcement for severe conditions

Spacer ring compatibility ensures precise fitment and optimal lubrication flow

Quick and easy installation

Compatible with most common sealed and lubricated track pin systems

Available Versions:

Standard SKF Trackstar Seal – With polyurethane ring and nitrile energiser

Heavy-Duty Trackstar Seal – Reinforced with a metal ring for high-rigidity applications

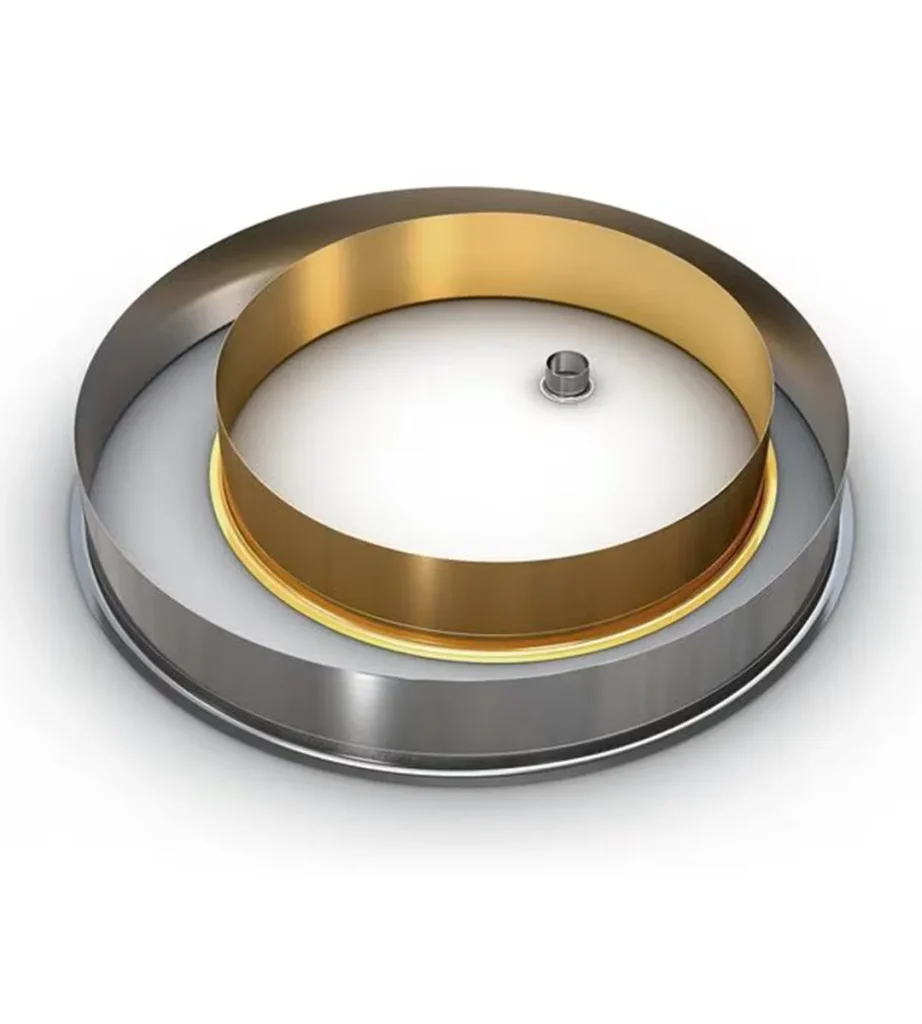

Metal face seals

Durable Sealing Solutions for Extreme Environments

SKF metal face seals are built to perform in the harshest operating conditions—where exposure to dirt, mud, water, and abrasive materials is constant. Designed for low circumferential speeds, these seals offer superior reliability by keeping contaminants out and lubrication in.

Originally developed for off-road and tracked vehicles, SKF metal face seals are now trusted in multiple high-demand sectors, including:

Mixers and sand treatment equipment

Conveyors and construction machinery

Agricultural machinery

Washing and grinding systems

Ore dressing and mining operations

Their rugged design and robust materials make them ideal for applications where conventional seals fail.

V Ring Seals

SKF V-ring seals are axial shaft seals designed to protect bearings and rotating components by excluding contaminants such as dust, dirt, and water. These seals also retain lubrication, making them a versatile choice for a wide range of industrial applications.

Available in a broad selection of stock sizes, V-rings can also be custom-manufactured for shaft diameters over 2,000 mm or unique operating requirements.

V-Ring Options:

All-Rubber V-Rings – Standard design, offering excellent flexibility and ease of installation

MVR Seals – Metal-cased V-ring seals for added rigidity and performance in more demanding environments

Whether you’re sealing in light-duty applications or heavy industrial systems, SKF V-ring seals deliver reliable axial sealing and extended equipment protection.

Maximize Protection With SKF Seals

Reliable Sealing Solutions for Demanding Applications

As an authorised reseller of SKF seals, E Rail Trans delivers high-performance sealing solutions that safeguard equipment, improve efficiency, and extend component life. Poor sealing can cause costly contamination and system failures, so choosing the right seal is essential for reliable operation.

Axial Clamp Seals

SKF axial clamp seals are designed specifically for large and very large shaft diameters, offering robust sealing in harsh environments. They are ideal as primary or secondary seals in applications where excessive exposure to solid or fluid contaminants is present. Unlike typical rotary seals, axial clamp seals remain stationary and seal axially against a rotating counterface.

Manufactured from profiled strips of non-reinforced nitrile rubber, these seals are secured in place with durable stainless steel band clamps, ensuring reliable fitment and performance.

Key Features:

Designed for shaft diameters ranging from 150 mm to 4,600 mm (5.9 in. to 181 in.)

Suitable for both inch and metric-sized shafts

Effective sealing solution for contaminated or abrasive conditions

Easy to install and maintain

Machined Seals

SKF machined seals offer a highly adaptable and fast-response sealing solution for a wide range of fluid power and power transmission applications. These seals are custom-manufactured using the innovative SKF SEAL JET production system—allowing for virtually any seal, in any size or design, to be produced quickly and accurately.

Machined seals are designed to deliver maximum sealing efficiency, with minimal friction and wear throughout their service life. Whether you’re sealing in dynamic or static systems, SKF’s materials and designs ensure top-tier performance across demanding industrial applications.

Key Applications:

Fluid Power Seals – Transmit power via fluid pressure with exceptional reliability

Power Transmission Seals – Seal the interface between rotating and stationary components

Seal Categories Available:

Piston Seals – Ensure reliable sealing between the piston and cylinder bore in hydraulic systems.

Rod Seals – Prevent fluid leakage along the piston rod in dynamic motion.

Wiper Seals – Keep contaminants out by wiping dirt and debris from the piston rod.

Guide Rings – Provide precise alignment and reduce wear between moving parts.

Back-Up Rings – Support soft seals under pressure and prevent extrusion.

Static Seals – Maintain tight sealing in non-moving applications such as flanges or covers.

Core Functions of Power Transmission Seals:

Retain lubrication

Exclude contaminants

Separate different fluids

Withstand pressure variations

For fast, tailored, and reliable sealing—choose SKF Machined Seals.

Industries we are passionate about

eRail Trans is known for its specialised, high-quality oil, lubricants, and advanced equipment supplier for the government and commercial industries. Our tailor-made solutions are designed to achieve maximum performance, while the top-of-the-line equipment is engineered to enhance efficiency and safety. Our reputation as a trusted partner is built on its unwavering attention to detail and innovation at its core.